|

|

| From the Swedish magazine Livsmedelsteknik, no 3,1996 page 31-33, translation | |||

| Could modern medical surgery lead the | |||

| way for the cutting and deboning trade? | |||

| The IT-branch is constantly developing. Virtual Reality (VR) is now used in practically all states in Research and Development. Remote-controlled brain surgeon is no longer an unachieved goal thanks to VR. The Swedish Meat Research Institute (SMRI) has accomplished the first research project in the world to cut meat fully automatically using VR technology as base. | |||

| Steen Herlevsen | |||

| Production engineer B.Sc., Swedish Meat Research Institute | |||

| The job to cut carcasses is heavy labour which is carried out in a high speed and in a cold environment. It is a craft and technology that take several years to fully command. The work is heavy and consists of fairly short work cycles. It is the same group of muscles that are constantly being used. Unfortunately, the body is not constructed for this stress. Many are granted an early retirement pension or are compelled to change professions. More than 90% of the sickness within the branch are due to heavy work. It is therefore every reason to develop methods that will ease the load. |

| Several Research and Development projects within fully automatically cutting, have been launched in New Zealand, Australia, England, Denmark and above all in France, where several hundred million crowns have been invested. In New Zealand mechanical sensors are often used. AMARC in England has invested a substantial sum at "force feed back" sensors. |

| France has been using the "learn by error" technique when programming the cutting robot. Research and trials with different sensors are constantly taking place in Denmark. Even the Danes prefer often mechanical sensors. SMRI is the first to simulate cutting and sensor technique in VR environment. |

| The principle for Virtual Reality |

| Instead of real physical prototypes, prototypes in a three-dimensional world are produced. The designer makes a drawing of his prototype in a thread model which are coated with surfaces that correspond to the choice of material. The surfaces’ hardness and other parameters are defined and if a robot is used, it is constructed in the same way. The same applies to the vision system, sensors, tools etc. The programming starts when the visual prototype is constructed. The control system of the robot is integrated as well as the vision system, sensor signals and separate programs for implementation controlling to a functioning unit. The designer discovers very soon the difficulties and can change the system. |

| Critical problems can be tested in reality when everything works. |

|

|||

| Medical brain surgery |

| A CAT scanner is placed around the patient’s head before the surgery starts. The CAT scanner scans the brain layer by layer and sends the signals to the graphic model which shows the inside of the brain in real time and, thanks to graphic, in an extremely high resolution. |

| The operation is preceded by a thorough preliminary investigation of the patient with VR technique, X-ray pictures and a conference with different specialists. The operation is planned and the way to the tumour is established, based on the actual case, previous experiences etc. When the preparations is done and the patient made unconscious, a small hole in the skull bone is drilled and the instrument is fixed in front of the hole. The surgeon is comfortably placed in a chair and has a VR screen on the head. His or hers visual sight is controlled by one of the hands and the instrument with the other. All participants of the operation can pursue the operation on a screen in or beside the operating theatre. The surgeon who is operating can control the instrument with the enlargement technique. The surgeon can, so to speak, pass around the tumour, observe it and at the same time see the instrument in relation to vital organs. |

| It is important to point our that the described procedure has not yet been carried out in reality, although, the installation is available at several German and American clinics where it is used for practising and education. |

| Deboning of pork loin |

| The cutting of meat is of course a much more "coarse" treatment than medical surgery, but there are similarities. The biological variety is one, there are not two animals that are exactly alike. The precision of handling on the contrary is much less critical. It is possible to use a rougher and cheaper technique, a vision system. In the project was used an exact model of the pork loin bones. The pork loin bones was cleaned completely and then drawn graphically. See picture 1. |

| The scientific achievements in the research in the present project have been carried out by a team under Norbert Lay, Fraunhofer Institutet IPA i Stuttgart which is one of Europe’s most prominent research institute regarding production development. The research was financed by Arbetslivsfonden (a Swedish government fund for OH) and Scan HB (Sweden’s biggest meat cutting company) in Kristianstad, Sweden. |

|

The head of the cutting department,

Kenneth Persson and 15 others, such as foremen, workers, physiotherapists etc. from Scan

HB participated actively in the project. - The technique is going to be developed in

accordance with the biological variation so that the technique can be transferred to other

meat parts and animal types in the future. Virtual prototype The prototype was constructed in the VR, see picture 2. All vision systems, 2D and 3D, colours and grey scale, available in the market incl. X-ray were tested. The best turned out to be 2D grey scale vision. Different automatic cutting tools such as electronical, pneumatical and hydraulical, were tested. The best turned out to be the hydraulical. The hydraulic knife cuts the meat without moving it, which is a big advantage. The robot has no power of its own whereas the power to the knife must be obtained from the outside. Different types of sensors were tested, but we believe for the moment that some kind of force feed-back sensors are the best. |

|

| Picture 2: Gripping appliance |

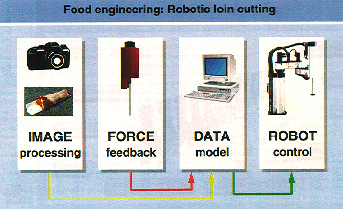

| Controlling of robot and knife A water resistant robot has been chosen. The movements of the robot are established at the standard model and are adopted to the biological variation. The current pork loin is modelled up by the vision system and the robot is fed with the desired cutting path. All information from the vision system and the sensors enter the control system, which by means of Fuzzy Logic Control, come to a decision about the robot’s further cutting path. See picture 3. |

| The knife is fixed on a knife holder, which can adjust more

exactly the precise placing and inclination of the knife. The knife holder is equipped

with its own movements and sensor system to be able to adjust very quickly in order to

avoid head-on collision with the bones. The control system of the robot is not quick

enough to adjust and avoiding instant collisions. The overall control system is an adaptive neural network. The knife holder is pre- programmed (in VR) with a number of problem solution’s activities which are different along the cutting path. If this is not enough, the robot will come to a stand still and the operator must show the system how the problem is to be solved. The operator’s interference is stored in the memory and added to the systems data base concerning solutions in order to solve similar problems in the future. (Learn by error.) |

|

Physical prototype next step As can be concluded from the above, the difficulties are primarily about the knife holder system and development of reliable sensor technique. Practical experiments are to be carried out over the next months in order to establish which sensors that are most reliable and fast enough to control the knife. When this has been settled, a substantial part of the economical risk is put out of the way in order to accomplish a physical prototype and the possibilities for further investments made easier. |

| Picture 3: By means of so called Fuzzy Logic Control, decisions about the robot’s further cutting path are effectuated. |